Why fiber laser marking is more suitable for metal micromachining

It is an indisputable fact that in the applications of various industries, especially in the medical, automotive and electronic industries, the required components are getting smaller and smaller.

The market is using new micro-machining technologies, including advanced laser marking machines with excellent beam quality , to obtain processing results similar to traditional processing technologies, but the processing methods are cheaper, faster and more flexible. The cost of fiber laser marking technology can be two to three times cheaper than traditional processing technology.

Mass manufacturers seeking to reduce manufacturing costs while meeting miniaturization processing challenges can use single-mode fiber laser marking machines to achieve superior processing on a range of materials including steel, nickel, titanium, silicon, aluminum, and copper effect. Manufacturers who are considering adopting the new process and may switch to 532nm and 355nm lasers can consider using fiber laser marking machines.

Microfabrication: only see results, no details

Micromachining refers to the use of standard machining operations such as drilling, cutting, scribing, and grooving to make very small features. In fact, there is no official size standard to determine when an operation is micromachining, but a good rule of thumb is that these features cannot be seen without the aid of auxiliary observation tools, or you can only see the results , But can’t see the details. In other words, you may not know what to do with the material to achieve a specific processing effect. For example, if you drill a 50 μm hole in a piece of copper, you will only see light, but you will not be able to see how large or small the hole is through which light passes.

Fiber laser marking machine: the right micromachining tool

In the hands of a skilled operator, the latest advances in using fiber laser marking machines for micromachining can create the desired features. The main advantage of this method is that fiber laser marking machines are two to three times cheaper than traditional equipment for micromachining. Successful micro-machining of small dimensions requires not only the right tools, but also knowledge of how to use the tools to achieve the desired results, while also considering the quality and speed of material removal.

Independent control of pulse width and peak power has significant control advantages and process tunability compared to traditional Q-switched lasers (which provide fixed pulse width / peak power settings). A scanning head that rapidly moves the laser beam is also a key part of the system, which needs to provide sufficient high-speed motion with appropriate repeatability and accuracy.

Fiber laser micromachining technology can be used in a variety of applications, such as for selective removal of solder masks, scribing and drilling of solar cells, drilling of stainless steel for medical low carbon steel pipes and fluid flow control systems, and for Rapid part prototyping cuts metals under 0.02 inches thick.

Fiber Laser Marking Machine Vs. Other Micro Machining Technology

Single-mode fiber laser marking machines can replace more expensive micromachining technologies, including EDM equipment or Nd: YVO4 lasers at 532nm and 355nm.

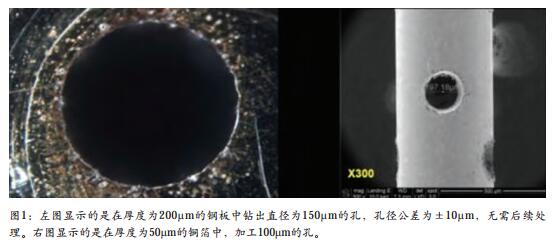

Figure 1 shows that fiber laser marking machines can replace EDM machines. The figure on the left shows the use of a fiber laser marking machine to drill a hole with a diameter of 150 μm in a steel plate with a thickness of 200 μm. The hole tolerance is ± 10 μm, and no post-processing is required. Using only 50% of the time required by EDM equipment, the fiber laser marking machine achieves the smallest amount of debris and tight aperture tolerance processing.

In addition, because the laser marking machine provides an XY work area, it can complete multiple parts in a single loading operation, which is also different from EDM equipment (unless an additional investment in motion equipment). This advantage makes the return on investment (ROI) of fiber laser marking machines more attractive. The fiber laser can also process thin materials and foils, which are difficult to process. As shown in Figure 1, it can process copper foil with a thickness of only 50 μm.

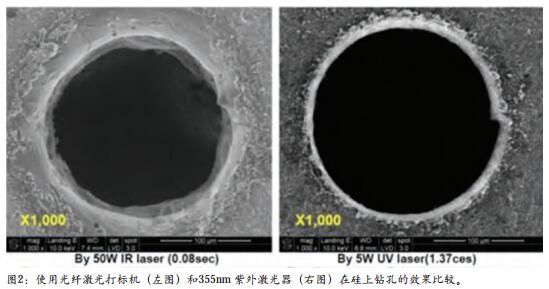

Figure 2 shows the results of drilling holes in silicon using a fiber laser marking machine (left) and a 355nm UV laser (right). While UV lasers can provide more than a fiber laser better processing quality, but for this particular application, the fiber laser processing effect is good enough, the processing quality is sufficient to meet the application requirements. In addition, the processing speed of fiber laser is 17 times faster than that of UV laser, and its cost is only 50% of that of UV laser. Due to the laser path program error, the roundness of the hole processed by the UV laser is slightly defective.

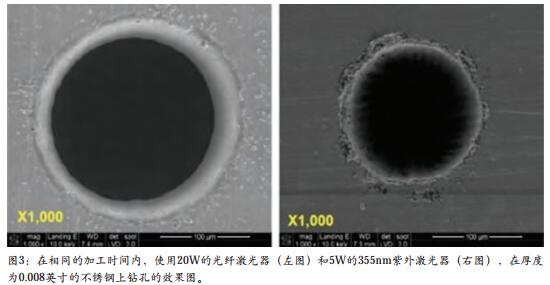

Figure 3 compares the effect of drilling holes in stainless steel with a thickness of 0.008 inches using a 20W fiber laser (left) and a 5W 355nm UV laser (right) in the same processing time.

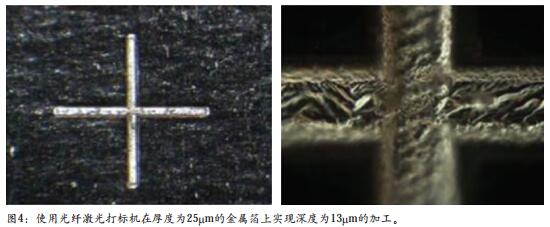

Figure 4 highlights the fineness and processing control possible with a single-mode fiber laser. Here, a fiber laser marking machine is used to achieve a 13 μm depth on a 25 μm thick metal foil. The processed channel width is 75 μm, and the depth variation in the entire area is ± 1 μm.

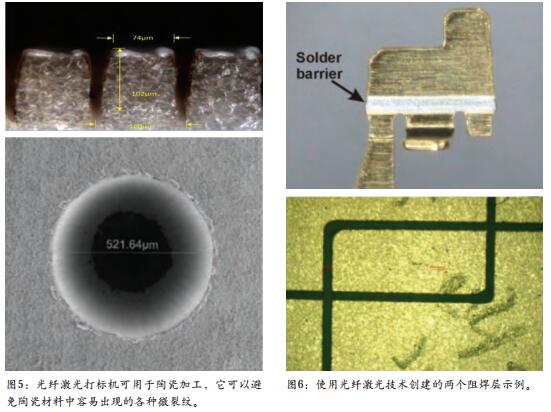

Ceramics are also a common material in microelectronics. UV lasers at 355 nm are commonly used for scribing and drilling ceramic materials. Figure 5 shows that the fiber laser marking machine can be used for ceramic processing because it can avoid various micro-cracks that easily occur in ceramic materials.

There are many applications that require (or can benefit from) the selective removal capabilities of lasers, such as removing plating or coatings on metals, ceramics and even plastics. Fiber laser processing technology has shown good processing results in microfabrication of solder resist, trimming of thin film resistors / capacitors, and removal of active layers in battery foils for welding purposes. This selective and customized layer removal process is often not possible during the production of components or parts, because simply masking the area is not a viable method.

Lasers are very useful in selecting the exact resistance value of a circuit. When used for resistor or capacitor trimming, as part of the dynamic iterative removal and measurement adjustment process, where the removal area of each component may be different, laser processing technology performs very well in this type of application.

Two examples of solder mask generation using fiber laser technology are shown in Figure 6. For each part, the laser selectively removes the gold layer. After the gold coating, the laser can be used to selectively remove material; this is a fast process and works well.

Single-mode fiber laser marking machine is a cost-effective micromachining workstation. Single-mode fiber laser marking machine can be used as a cost-effective micromachining workstation to provide drilling, cutting, scribing for various applications. And ablation processing. Of course, it can also be used for marking! This benchtop miniature machining center offers many advantages to maximize your return on investment.