New progress of fiber laser application in engine drilling

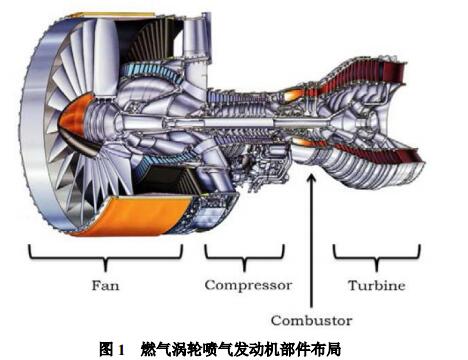

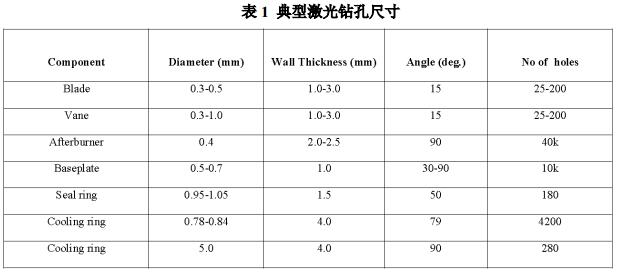

Modern turbine engines need to drill many holes during the manufacturing process, and the processing of various parts of the gas turbine also requires laser drilling. As shown in Figure 1, the component blades, vanes, burners of the gas turbine jet engine and mainly used for cooling Afterburner. The number of holes required for each part ranges from 25 to 40,000, as shown in Table 1. The gas temperature of modern jet engines may be as high as 2000 ° C, which is higher than the melting point of nickel-based superalloys in combustion chambers and turbine blades. The current method to protect jet engine components from extreme temperatures is boundary layer cooling. When the cooling air passes through its surface, a cooling film is formed to protect the surface of the component from high-temperature combustion gases.

Cooling holes can be machined by electric discharge machining (EDM) or laser . The EDM contains an electrode that creates a small gap between two surfaces on the workpiece. A voltage is applied between the electrode and the workpiece until the electric field can penetrate the tip of the electrode. The spark discharges through the gap and causes a high current density due to the small cross-sectional area, about 1000 A / mm2. The typical temperature of the breakdown area between the electrode and the workpiece is 5000-10000 ° C, and the EDM process uses discrete discharge drilling. Although EDM can produce high-quality holes, it is actually slower than lasers, and this technology has some disadvantages.

For laser drilling, high-peak power pulsed Nd: YAG lasers have always been the preferred choice for commercial drilling and military aero engine parts processing. The selection of pulsed Nd: YAG lasers is mainly based on the following aspects:

1. Good coupling of 1.06μm radiation to components (whether in terms of material absorption or plasma avoidance)

High pulse energy and peak power are ideal for this application

3. Achieve high aspect ratio of pores at a very high speed in various materials, including thermal barrier coating materials

Currently in the field of aerospace applications, there are two different laser drilling technologies, namely drilling and impact drilling. Perhaps the most popular is the true cutting technique, which is perforation of the head. The laser beam pierces the workpiece just on the periphery of the hole, then tracks the perimeter outward, and then cuts the correct diameter by rotating the workpiece or the laser beam hole. This technology can produce high-quality holes, roundness and hole variation and numerical control Processed just as well. The taper of the hole also meets the quality requirements.

The second drilling method is impact drilling. This technology requires a laser to emit laser pulses to the workpiece , and then turns the material into a liquid melt by evaporating the material, and then removes excess material from around the hole. Both sides of the hole wall sprayed out. It is difficult to control the quality of the holes using this drilling technology. Only by strictly controlling the drilling parameters can high-quality holes be produced. The advantage of this drilling technology is the fast processing speed. The combination of percussion drilling with another technique called in-flight drilling has more advantages. The method of drilling in flight is to punch and punch the laser pulse while the workpiece or laser moves continuously.

The problem of hole quality is a very important and subjective problem. The judgment of hole quality produced by laser drilling has different characteristic parameters. The geometric factor is the hole roundness, hole taper, and hole entrance diameter variables. The metallurgical factor is oxidation and recasting. Layer, the recast layer is a molten material that has not been ejected by the vapor pressure of the laser pulse. The coating of the recast layer will leave a thin layer on the surface of the solidified metal. This thin layer will cause microcracks, which will affect the parent material. For airlines like Rolls-Royce, they have a maximum allowable thickness for recast and oxide layers, but the geometrical factor of the hole has the largest deviation before the component is used in the engine. Other airlines are more focused on using the mobility of aviation components to judge borehole quality. No matter which method is used, airlines are constantly striving to improve the quality of drilling.

In order to meet the requirements of laser drilling for aviation applications , such as hole quality, period, new materials, etc., more efficient, compact and high beam quality lasers are needed , which has also promoted the development of high peak power fiber lasers (quasi-continuous wave). These lasers work in the near-infrared spectral region and have superior performance than traditional lasers, opening up new drilling prospects for lasers widely used in the aviation field. High peak power fiber lasers are more compact and rugged, surpassing lamp-pumped Nd: YAG lasers in both beam quality (M2 <10) and maximum socket efficiency of 25%. The main points of this new drilling machine can be summarized as follows:

1.Better beam quality-small diameter hole

2. Fiber lasers are not like Nd: YAG lasers with a recast layer at the focal point

3. Excellent pulse stability (pulse energy / pulse power)

4, wider working range-greater flexibility in process parameters

5. High pulse frequency, reducing the cycle time of the punching operation process

6. Simultaneous operation in CW and pulse mode