Cutting parameters and bright cutting techniques of Ruike high-power lasers, you don’t want to miss it!

Demand determines the market. Undoubtedly, the research and development and application of fiber lasers have developed to higher power, especially in the field of laser cutting , the application of high power lasers has become a general trend. Many companies are considering purchasing high-power fiber laser cutting equipment, but still have concerns: they all know that higher power can cut thicker and faster, but how thick is it? How much faster? What other advantages are there? To this end, Ruike engineers have compiled the advantages analysis and parameter comparison of high-power fiber laser cutting, I believe it will definitely help you.

Advantage one: the cutting limit thickness is greatly improved

The cutting thickness of Ruike 12kw fiber laser reaches more than 40mm, and the carbon steel reaches 50mm.

Pictured above are 40mm carbon steel, stainless steel and aluminum alloy

The picture above shows a 50mm carbon steel cutting sample

Compared with lower-power lasers, the cutting capability has been improved by qualitative overshoot, which has greatly improved the processing range of laser cutting machines .

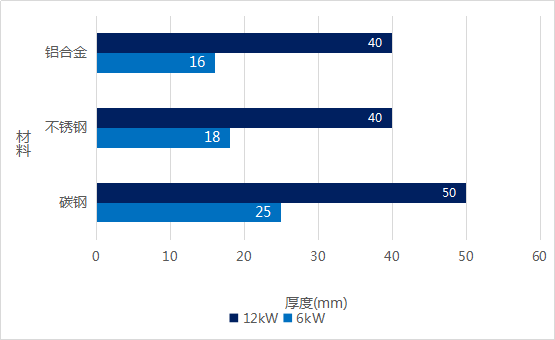

Comparison of 12kw and 6kw cutting limit thickness

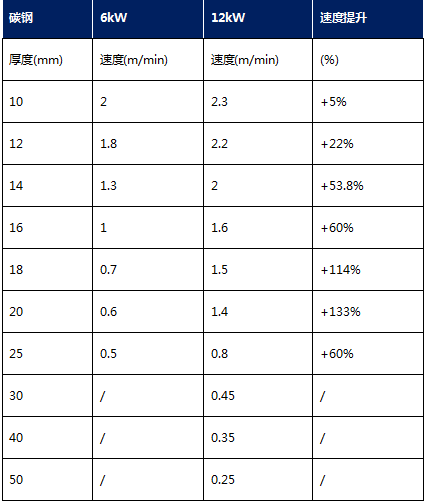

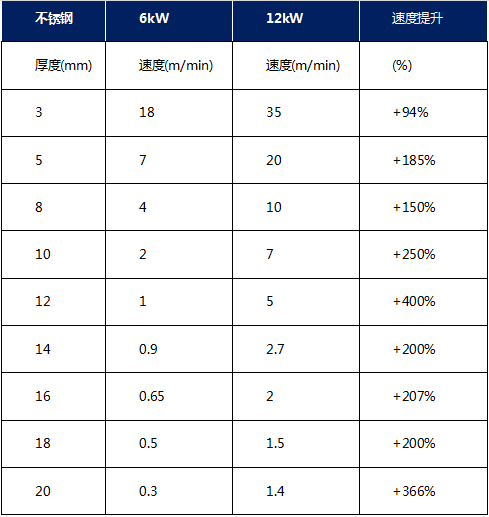

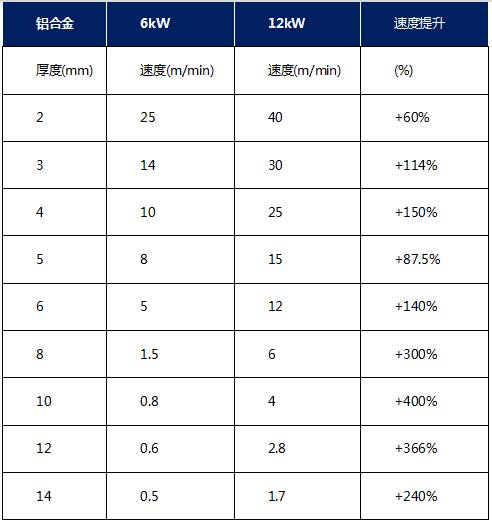

Advantage two: greatly improved cutting speed

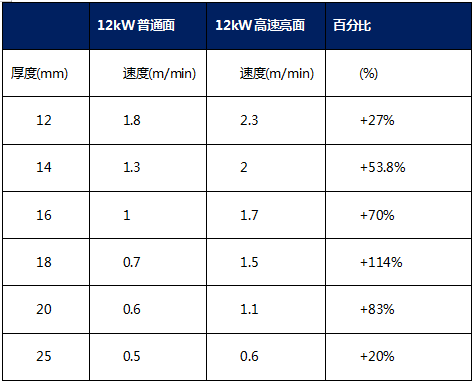

When selecting the power of the laser cutting equipment, the cutting speed of different materials is the key factor to consider. Fiber laser cutting applications have significant advantages in the processing of medium and low thickness plates. The increase in laser power can increase the cutting speed doubled.

The increase in speed brings an exponential increase in the economic benefits of fiber laser cutting machines. Especially for the medium-thickness materials of current fiber cutting, the cutting speed can be increased by more than 2 times.

Advantage three: increased diversity of cutting processes

In addition to the advantages of thicker and faster cutting, as the laser power increases, the laser cutting process can play more tricks. For example, the now highly acclaimed high-speed bright surface cutting technology and thick plate small hole cutting technology.

l High-power high-speed bright surface cutting technology (HHB, Highpower, Highspeed, Brightsurface)

That is, when the power is sufficient, small nozzles, small air pressure, and high-power lasers are used to cut carbon steel plates of different thicknesses at high speed to obtain smooth cutting sections and smaller processing tapers. The smooth cut surface is convenient for customers’ subsequent processing. At the same time, the taper can be controlled below 0.2mm on both sides. In some processing industries with high precision requirements, it can better meet customer requirements.

The picture above shows the high-speed bright surface cutting sample of Ruike 12kw laser for 12-20mm carbon steel.

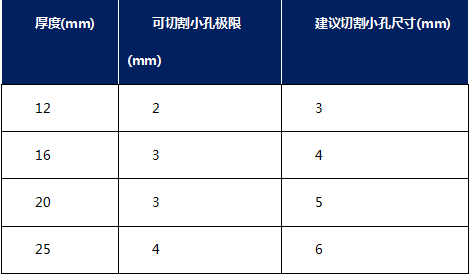

l Thick plate small hole cutting technology

Based on the extension of high-speed bright surface cutting technology, we have developed a small hole cutting technology for thick plates, which can cut high-quality small holes with a diameter smaller than the plate thickness on thicker plates. , Cut small holes with a diameter of 3-5mm and can process stably.

High-speed bright surface cutting process tips

With the continuous development of fiber laser technology, the market has increasingly higher requirements for fiber laser cutting effects. Among them, the high-speed bright surface cutting process of carbon steel materials is increasingly sought after. So how to achieve fast and good carbon steel bright surface cutting? Ruike process engineers share three cutting conditions that must be met:

Small nozzle: double nozzle, between 1.0-2.0mm;

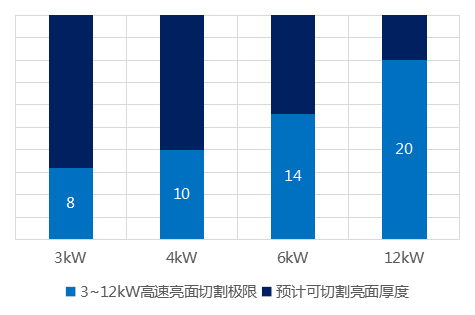

High power: The higher the power, the greater the limit thickness of the bright surface of carbon steel that can be cut, and the efficiency will be significantly improved;

Atmospheric pressure: most between 0.6-1.2Bar

In actual operation, not only need to meet these conditions, but also professional debugging to achieve stable and consistent results. Ruike engineers can provide you with professional technical support for free.

Ordinary surface cutting

Bright cut

Ordinary surface cutting: 0.4mm to 1mm on both sides of taper

Bright cut: within 0.2mm of taper on both sides